Packing robot

Team: Khoa Tran (individual)

Year: 2020

Keywords: robotics, pattern packing, agriculture, eCommerce

The problem

Help LYRO Robotics, a promising deep-tech Australian start-up based in Brisbane, commercialise its smart robot prototype and establish its position on the market.

The outcome

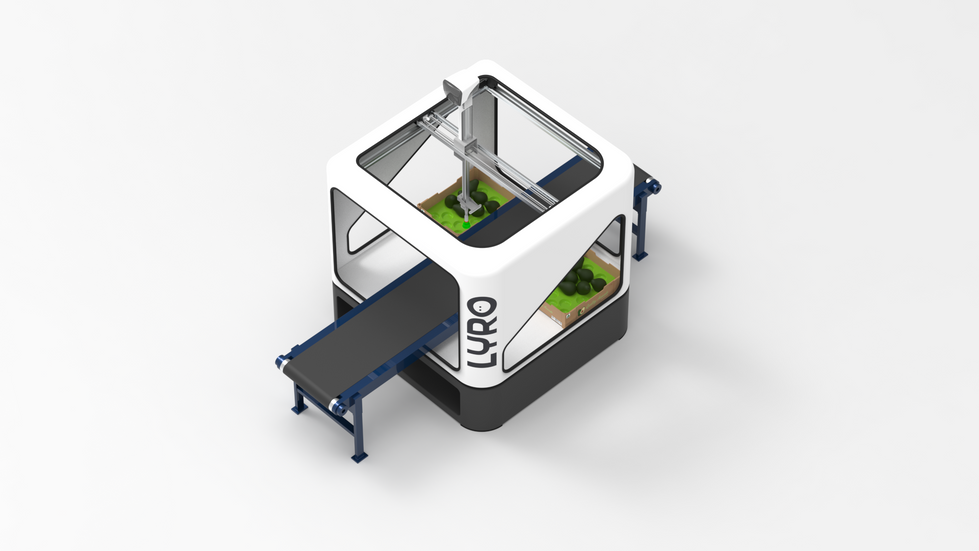

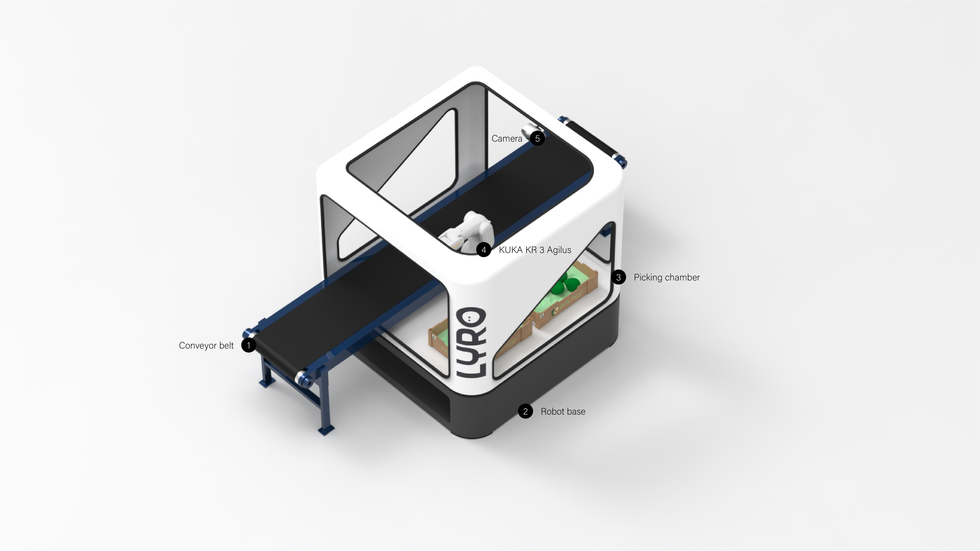

A new modern housing for LYRO's intelligent fresh produce pattern-packing robotic system.

The impact

The new housing not only helps convey LYRO's vision and philosophy but also establishes the company's long-term goals of integrating its research-driven advanced robotic picking and packing solution into other areas such as retail and e-Commerce.

RESEARCH

Artificial intelligence is growing rapidly and the power of smart robots is being harnessed in various areas such as healthcare, agriculture, and manufacturing. LYRO seeks to utilise machine intelligence to improve efficiency and productivity by freeing people from undergoing dangerous, dirty, and dull tasks and ensuring a robust, safe, and secure supply chain.

USER GROUP

Packhouse workers

Need a way to escape from dull or dangerous tasks while maintaining a sense of job security.

Packhouse owners

Need an efficient approach to packing fresh produce during labour shortage.

FEATURES

Configuration 1: XY plotter

This configuration utilises the mathematical principle of cartesian plane to identify, pick, and relocate items with a high level of precision.

Configuration 2: Franka Emika Panda

This configuration utilises the Franka Emika Panda robot arm manufactured by LYRO's global partner from Germany, Franka Emika.

Configuration 3: KUKA KR 3 Agilus

This configuration utilises the KR 3 Agilus robot arm manufactured by LYRO's global partner from China, KUKA.

SEQUENCE OF USE

As this project contributes to forming a new product line, I have used speculative design to envision LYRO robotic system within several scenarios. This is an effective way to visually encapsulate the company's vision and communicate my design language.

Scenario 1: Pack house - single robot with sorting system

After the robot has finished picking items from a tote box to a shipping box, the blue conveyor belt is programmed to divert the next full tote box to the robot's chamber.

Scenario 3: Packhouse - single robot and feeder system

The items from the feeder system are diverted directly to the robot's chamber to be placed into shipping boxes.

Scenario 2: eCommerce fulfilment centre - single robot

Full tote boxes are diverted to the robot's chamber and the items are transferred from these boxes to shipping boxes.

Scenario 4: eCommerce fulfilment centre - robot fleet

Full tote boxes are diverted to the robot's chamber and the items are transferred from these boxes to shipping boxes.

DEVELOPMENT

Design development

This process involves various types of sketches including styling sketches, final design sketches, and feature design sketches.

PROTOTYPE

Prototype teaser

After the internship has concluded, I have passed the design to the engineering team at LYRO. As a result, LYRO's state-of-the-art technology has been successfully encapsulated in a brand new housing.