Unichvrge

Team: Khoa Tran (individual)

Year: 2019

Keywords: design for manufacture, phone dock, manufacturing process

The problem

Building on the skills and knowledge of common manufacturing processes, help a start-up company, Spin Electronics design a logo and a simple Arduino-based phone charging dock.

The solution

A simple universal phone charging dock that can charge a wide variety of smartphones.

The impact

Improved ability to design a product with a suitable level of aesthetics and usability within the constraints of manufacturing.

RESEARCH

USER GROUP

Students

Need an affordable phone charging dock that can accommodate many types of smartphones and fit into a study environment.

Office workers

Need an affordable phone charging dock that can accommodate many types of smartphones and fit into a study environment.

FEATURES

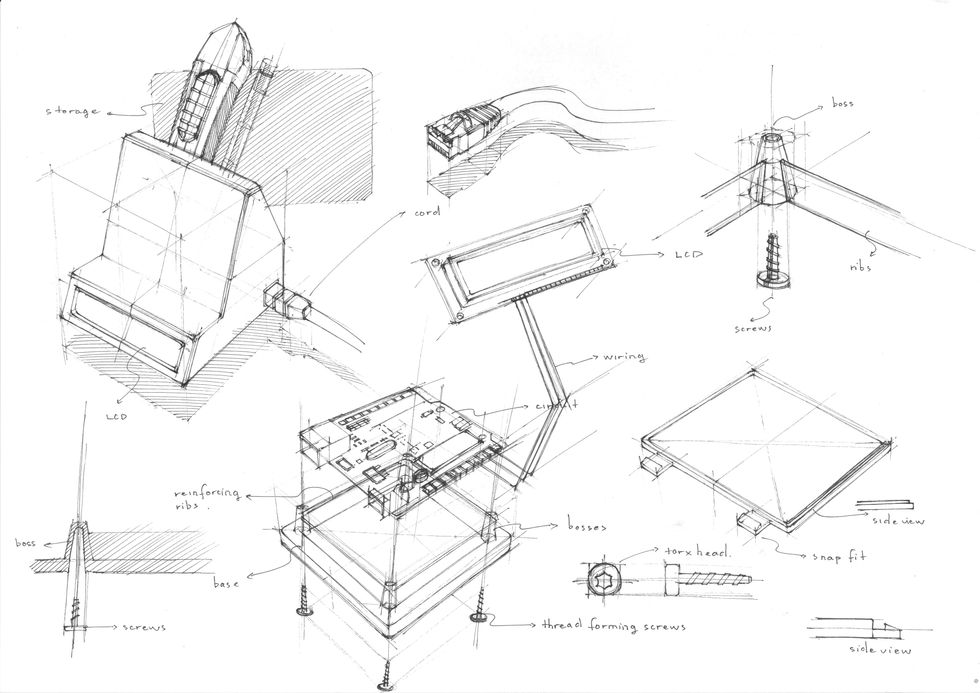

Exploded view

The product is primarily made of Acrylonitrile

Butadiene Styrene (ABS) which is one of the most commonly used plastics for injection moulding. It has many attractive characteristics such as high impact resistance and low shrinkage. Considering the chosen texture (i.e. Mold-tech MT-11000), ABS results in an excellent textured surface finish.

Hero shot

Designed with versatility and usability in mind, the product can accommodate a wide range of smartphones with multiple interchangeable charging heads. Unichvrge provides an expensive charging solution with the use of simple technologies. The product is available in 3 colour schemes including abyss (turquoise/bronze), genesis (navy/rose), and aurora (saffron/grey)

SEQUENCE OF USE

STEP 1: Plug the cable

The user plugs in the USB cable to power up the charging dock.

STEP 2: Remove

The dock is designed so that its user interface and the phone's screen are within the optimal range for displays, allowing easy eye and head rotation without fatigue.

DEVELOPMENT

Design development

This process involves various types of sketches including styling sketches, final design sketches, and feature design sketches.

Flow simulation

Computational Fluid Dynamics (CFD) solution to simulate the flow of plastic during injection moulding.

PROTOTYPE

Rough prototype

Rapid prototyping using foam is an efficient way to test design ideas and inform the design decision process regarding form and overall dimensions.

Final prototype

The final prototype was carefully finished with spray paint and primer to achieve a high-quality polished appearance.